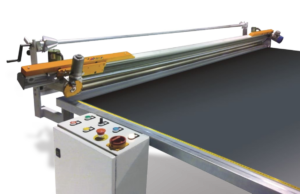

STATIC AUTOMATIC CUTTER FOR HEAVY FABRICS

PROFESSIONAL CUTTING FOR DEMANDING MATERIALS

The static automatic cutter from AUTEX has been specially developed to meet the production needs of companies working with heavy, thick, or padded fabrics. Thanks to its solid structure and high-precision assisted cutting system, this machine offers the perfect balance of power and control, delivering clean, uniform cuts even on bulky or dense materials.

TECHNICAL SPECIFICATIONS

This solution easily adapts to different production environments, as it is available with either a fixed or mobile table, allowing optimal integration depending on each plant’s space and workflow. It features a 30 mm diameter roll holder bar with sturdy supports, making loading and positioning easier—even with large rolls up to 350 mm in diameter.

One of the most valued features by operators is the adjustable cutting speed, which makes it easy to work with different fabric types without compromising accuracy. It also includes a fabric press system that secures the material during cutting, preventing any shift or deviation. An integrated sharpening system ensures clean cuts and extends blade life.

For daily operator comfort, the machine is ergonomically designed with a 900 mm table height and 1100 mm loading height. It includes fabric clamps that enhance the hold of the press system, providing maximum stability during operation. A roller cradle version is also available, ideal for continuous or assisted fabric feeding.

Powered by 220V, the machine is quick to install and integrate in industrial settings without the need for major electrical modifications. This makes it a robust and versatile tool ready to meet the demands of technical and fashion textile production.

KEY ADVANTAGES

Specialized in working with complex and heavy fabrics, this cutter ensures clean, repeatable cuts throughout every cycle. Its adjustable speed, fabric holding system, and overall structural stability allow operators to work with safety and confidence. The flexibility to choose between different table setups and to add a roller cradle makes it a highly adaptable solution for various production schemes.

Its modular design and ease of use ensure that your team can operate the machine efficiently from day one, with minimal training and high productivity from the very beginning.

A solution designed to boost productivity without compromising cutting quality.

Contact our team for customized versions and delivery times.